Rigid-Flex PCB: The Ultimate Guide to Manufacturing, Features, and Benefits

Rigid-Flex PCB: The Ultimate Guide to Manufacturing, Features, and Benefits

Introduction:

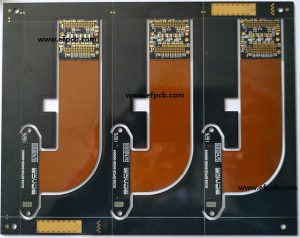

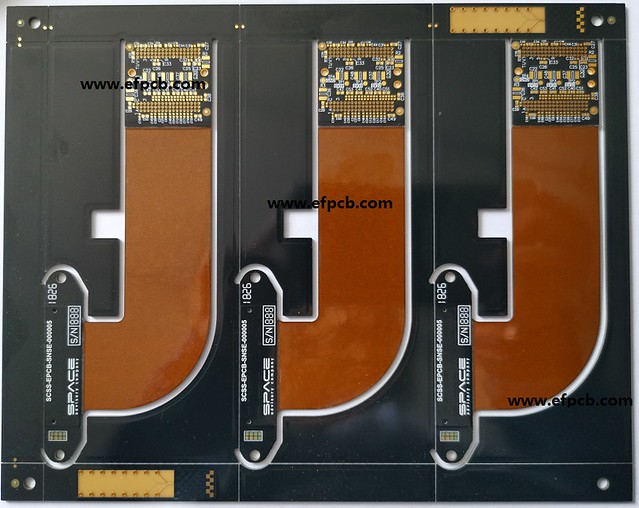

In today’s fast-paced world of electronics, the demand for advanced circuitry continues to grow. Rigid-flex PCBs have emerged as a revolutionary solution that combines

the best of rigid and flexible boards. In this article, we will delve into the manufacturing process, features, advantages, and usage methods of Rigid-Flex PCBs – an indispensable component in modern electronic devices.

Manufacturing Process:

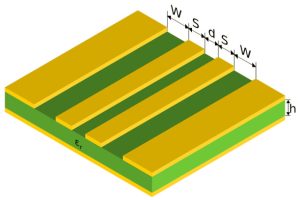

Rigid-flex PCBs are manufactured using a specialized technique that involves combining traditional rigid Rigid-flex PCB manufacturer boards with flexible substrates. This unique manufacturing process allows for three-dimensional circuits, eliminating connectors and providing greater design flexibility.

Characteristics: Rigid-flex PCB manufacturer

The structured-flexible PCB offers several key characteristics that make it stand out in the industry. Unlike traditional rigid or flexible boards, this technology provides both stiffness and pliability simultaneously. By integrating a stiff-yet-pliable circuit board with solid-flexible circuitry panels, Rigid-Flex PCBs offer unmatched durability and versatility.

Advantages:

1. Space Saving: One major advantage of Rigid-Flex PCBs is their compact size Rigid-flex PCB due to integrated components on a single board instead of separate interconnected modules.

2. Enhanced Reliability: With fewer solder joints in comparison to conventional assembly techniques, these boards exhibit increased reliability by reducing the risk of failure.

3. Improved Signal Integrity: The elimination of interconnecting cables minimizes signal loss while improving electrical per Structured-flexible PCB formance.

4. Simplified Assembly: Assembling complex electronic systems becomes more efficient due to reduced wiring complexity.

Usage Methods:

Rapid advancements in various industries have led to diverse applications for Rigid-Flex PCBs:

a) Aerospace Sector: These innovative boards are widely utilized in Solid-flexible circuitry panel aerospace applications due to their lightweight nature combined with robust structural strength.

b) Medical Devices: From implantable medical equipment like pacemakers to diagnostic machines such as MRI scanners – all benefit from the flexibility and reliability provided by Rigid-Flex PCBs.

c) Consumer Electronics: Portable devices like smartphones, tablets, and wearables require high-density packaging, making Rigid-Flex PCBs a preferred choice.

d) Automotive Industry: With stringent safety standards and increa Rigid-flex PCB sing demand for electronic features in vehicles, Rigid-Flex technology plays a crucial role in implementing various sensors and control systems.

How to Select the Right Manufacturer:

Choosing the right manufacturer is vital when it comes to ensuri

ng quality and reliability. Consider the following factors before making your decision:

1. Experience: Look for a manufacturer with extensive experience in producing Rigid-Flex PCBs across various industries.

2. Quality Control Process: Rigid-flex PCB Ensure that the manufacturer has robust quality control processes in place to deliver defect-free products consistently.

3. DFM Analysis Capability: Opt for a supplier equipped with Design For Manufacturability (DFM) analysis capabilities as it helps optimize designs for manufacturability and cost-effectiveness.

Conc Stiff-yet-pliable circuitboard lusion:

Rigid-flex PCBs have revolutionized modern electronics by offering unmatched design flexibility, durability, space savings, improved signal integrity, simplified assembly process, and diverse application possibilities. By carefully selecting an experienced manufacturer with strong quality assurance measures and DFM analysis capabilities – you can unleash the true potential of this remarkable technology. Whether you are developing cutting-edge aerospace equipment or consumer electronics – Rigid-Flex PCB DFM Analysis manufacturer s prove to be an invaluable solution leading us into a future of advanced technological innovation.