Title: The Versatility of Liquid Mixers

Title: The Versatility of Liquid Mixers

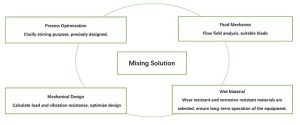

Liquid mixers, also known as solution agit liquid mixer ators, are essential devices in various industries. They provide efficient mixing and blending solutions for wet mixtures, molten substances, and dissolved materials. In this article, we will explore the manufacturing process, characteristics, advantages, proper usage methods, tips for selecting these machines from a Filling Machine Supplierliquid mixerliquid mixerliquid mixerliqui Filling Machine Supplier d mixer standpoint.

Manufacturing Process:

The liquid mixers are manufactured using high-quality materials such as stainless steel or other corrosion-resistant alloys. These materials ensure durability and longevity even when exposed to harsh chemicals or extreme temperatures. Skilled technicians assemble the components meticulously to create a reliable mixing dev solution agitator ice.

Characteristics:

Liquid mixers come in different sizes and designs to suit varying industry requirements. They consist of a motor-powered shaft attached to an impeller or propeller that rotates at high speeds within the container holding the liquid substance. This rotation creates shear forces and turbulence that facilitates thorough mixing by breaking down settled particles.

Ad liquid mixer vantages:

1. Efficient Mixing: Liquid mixers excel at effectively blending different liquids while dispersing insoluble solid part liquid mixer icles.

2. Time-Saving: By automating the mixing process with these machines’ help significantly reduces manual labor and time required.

3. Improved Product Quality: The uniformity achieved through liquid mixing ensures consistent product quality throughout production batches.

4. Versatility: From chemicals and pharmaceuticals to food processing i

ndustries, liquid mixers can adapt to various applications efficiently.

5.Ease of Maintenance:Cleaning these devices is relatively simple due to their accessible design elements.

Usage Methods:

To use a liquid mixer properly,

1.Perform Visual Inspection:Determine if any parts are damaged before setting up

2.Securely Install:Maintenance personnel must set up alignments appropriately after re wet mixture combining device moving dust caps & cover plates(if applicable)

3.Adjust Impellers:Set impellers according to substances being mixed; spinning at high speeds should ensure efficient blending.

4.Monitor Mixing Progress:Supervise the process to make sure it aligns with mixing goals.

How to Select a Liquid Mixer:

To choose the most suitable liquid mixer for your needs, consider:

1. Viscosity of Materials: Ensure the machine can handle substances with varying viscosities.

2. Container Size: Match the mixer molten substance mixer ‘s capacity to fit comfortably in your production vessels while providing adequate speed and power.

3. Material Compatibility: Check if t Filling Machine Supplier he materials used are resistant to corrosion or chemical reactions likely present during mixing processes.

4. Safety Features: Evaluate safety features such as emergency stops, overload protection, and automatic shut-off mechanisms.

In conclusion, liquid mixers play a significant role in various industries by efficiently combining we liquid mixer t mixtures, molten substances, and dissolving materials. The manufacturing process ensures durability and longevity while the machines’ characteristics deliver optimal performance. With their advantages of time-saving efficiency and improved product quality, selecting a suitable liquid mixer from Filling Machine Supplierliq

uid mixerliquid mixerliquid mixerliquid mixer is crucial for successful operations in any industry reliant on effective mixing techniques.

(Note: The above content is an example and does not guarantee accuracy regarding specific technical details.)